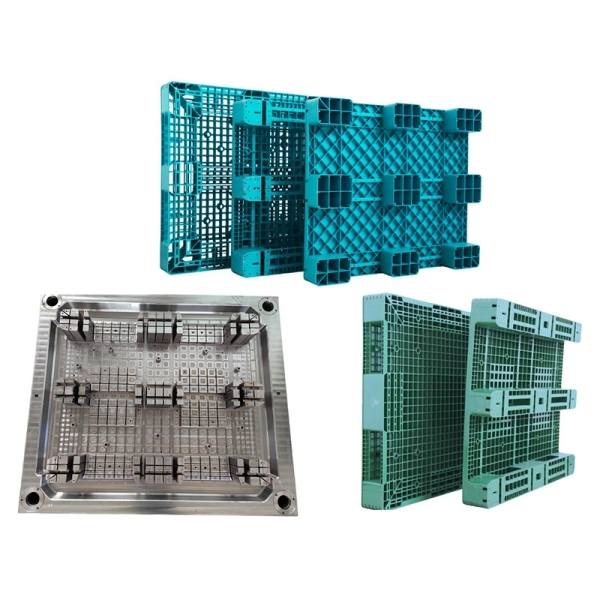

Product Details

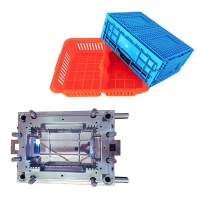

Comprehensive analysis of injection molding tray molds, combining market supply, technical parameters, and industry trends:

I. Market Supply and Price

Regional Concentration: Huangyan District in Taizhou, Zhejiang, is a major production area in China, accounting for 70% of the country's production capacity. Manufacturers offer customized services, with a wide range of quotations for a single mold set (from 500,000 to 4,860,000 yuan). The main differences arise from factors such as size (e.g., the standard size of 1.2×1 meters) and functional complexity.

Customized service: support steel embedded, anti-slip pattern and other designs, mold opening cycle 30-45 days, minimum order quantity is usually 50 sets, some manufacturers support one-piece delivery.

II. Materials and Processes

Mainstream materials:

HDPE: resistant to low temperatures (-50℃) and impact, suitable for cold chain logistics, priced at approximately 10,000 yuan/ton.

PP: High temperature resistance (≤120℃), high rigidity, suitable for medical sterilization scenarios, price is about 11,000 yuan/ton.

Injection molding equipment: Large trays require injection molding machines with a clamping force of over 3000t (such as the TRIULZI 55000/3000 model), and a hot runner system can reduce the scrap rate to less than 5%.

III. Technological Trends

Intelligent production: The molding cycle of the two-plate injection molding machine + robotic automatic line is shortened to 120 seconds per piece, and the energy consumption is reduced by 30%.

Environmental protection upgrade: The application rate of recyclable materials has been increased to 60%, and modular mold design has been implemented to achieve multi-model production with one machine.

For further screening, please refer to the 1688 injection mold section or the Huangyan mold enterprise directory.