Product Details

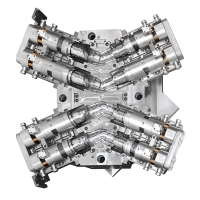

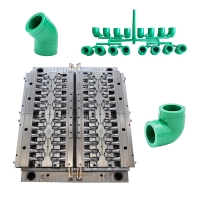

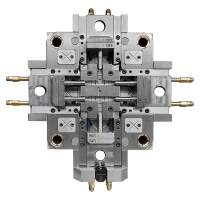

Hot melt pipe fitting molds are mainly used for the production of PPR water pipes and other hot melt connecting pipe fittings. After heating, the pipes and fittings are fused together. The following are the main types and key points for purchasing:

Common types

- Anti clogging mold head: suitable for 4-inch, 6-inch, and 1-inch water pipes, using DuPont material to enhance wear resistance and thickened design to prevent clogging.

- Extended anti blocking mold head: specially designed for special positions such as wall corners, making it easy to maintain and inspect.

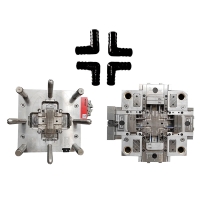

- Injection mold: used for producing PPR tees, elbows and other accessories, supporting customized mold opening services.

Key points for purchasing

- Material: Alloy steel or stainless steel materials are preferred to ensure durability and precision.

- Size adaptation: It is necessary to match the specifications of the water pipe (such as 20, 25, 32mm), and different specifications of molds cannot be mixed.

- Anti blocking design: Prioritize selecting molds with anti blocking structures to reduce maintenance frequency.